RA600 is designed for tire mold manufacturing, accurately reproducing complex tread patterns while improving productivity and reducing costs.

With ±0.1 mm precision, 3D printed tire master molds enable faster lead times and reliable production of highly complex designs.

Explore the key features of RA600, a high-precision SLA 3D printer for efficient and accurate tire mold production.

Operates unattended 24/7 with intelligent software that automatically generates printing paths, eliminating the need for manual programming.

Produces fine tread pattern details and complex geometries with ±0.1 mm accuracy, allowing creative and intricate tire mold designs.

Integrated prototyping without additional steel sheets shortens production cycles, boosts productivity, and significantly reduces costs.

Digital manufacturing reduces chemical usage and supports sustainable, cleaner tire mold prototyping.

On-demand printing enables zero-inventory operation, improving flexibility and reducing storage requirements.

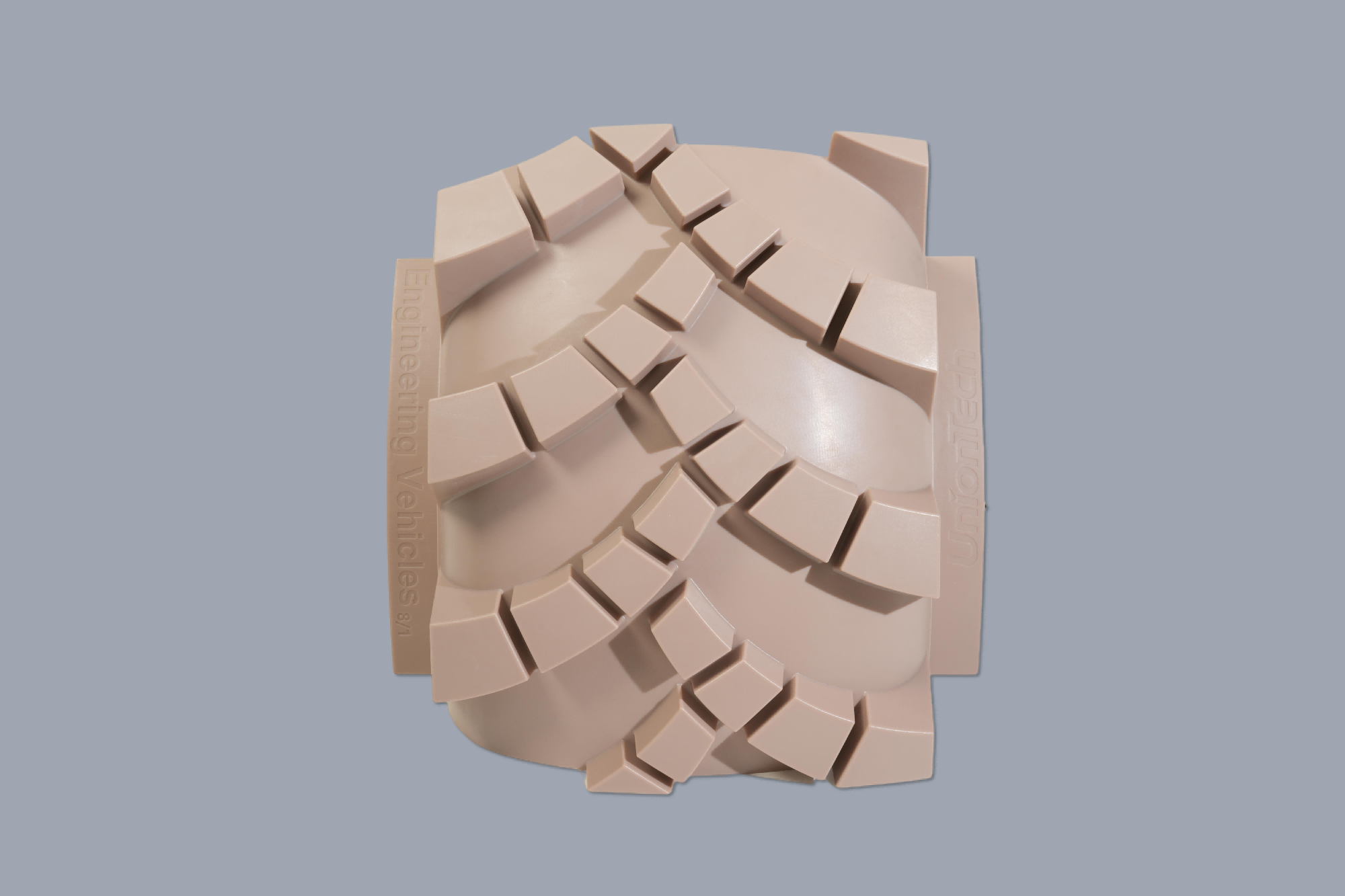

Examples of high-precision 3D printed tire molds produced with RA600, showcasing complex tread patterns and fine details.

| Build Volume | 600 × 600 × 400 mm

23.6 × 23.6 × 15.7 in |

| Accuracy | Dimension <100 mm: ±0.1 mm

Dimension ≥100 mm: ±0.1% x Dimension |

| Layer Thickness | 0.05-0.25 mm |

| Laser | 355 nm, solid-state frequency tripled

Nd: YVO₄ |

| Beam Focus | Dynamic & Variable |

| Beam Size | 0.12-0.8 mm |

| Scanning Speed | 8-15 m/s |

| Control Software | UnionTech™ RSCON |

| Operation System | Windows 10 |

| Data Interface | .stl |

| Network | Ethernet, IEEE802.3, TCP/IP |

| Electrical Requirements | 200-240 VAC, 50/60 Hz, Single Phase |

| Rated Power | 2.6 kVA |

| Systems Control | Closed-loop |

| Temperature Range | 72–79 °F (22–26 °C) |

| Maximum Change Rate | 1 °C/hour |

| Relative Humidity | < 40% |

| Resin Vat | Replaceable / Fixed |

| Machine Dimensions | 1375 × 1295 × 1930 mm

54.13 x 50.98 x 75.98 in |

| Machine Weight | 850 kg |

Consult with your sales representative for confirmation of current offering.

RA600 delivers a dimensional accuracy of up to ±0.1 mm, enabling precise reproduction of fine tread details and complex geometries that are difficult to achieve with traditional manufacturing methods.

Yes. As an industrial SLA 3D printer, RA600 excels at printing highly detailed and complex tire patterns, making it ideal for advanced tire mold design and innovation.

By adopting digital tire mold manufacturing, RA600 significantly shortens lead times, reduces manual processes, and lowers labor costs compared to conventional mold-making workflows. For example, customers such as LiChong Mould have reported efficiency improvements of over 80% after adopting the RA600 SLA 3D printer for tyre mould manufacturing.

RA600 is an industrial-sized SLA 3D printer built for continuous operation. It supports stable, repeatable production of tire master molds and prototypes in industrial environments.

No. RA600 is designed to integrate easily into existing digital design and manufacturing workflows. With UnionTech software, it simplifies data preparation, printing, and post-processing without requiring major changes to current production processes.